The Real-Time Manufacturing Intelligence Platform

Unify machines, data, and operations with AI-powered intelligence and secure IoT connectivity. Improve uptime, optimize performance, and enable data-driven decisions across the enterprise.

Unify machines, data, and operations with AI-powered intelligence and secure IoT connectivity. Improve uptime, optimize performance, and enable data-driven decisions across the enterprise.

Trusted by Industry Leaders

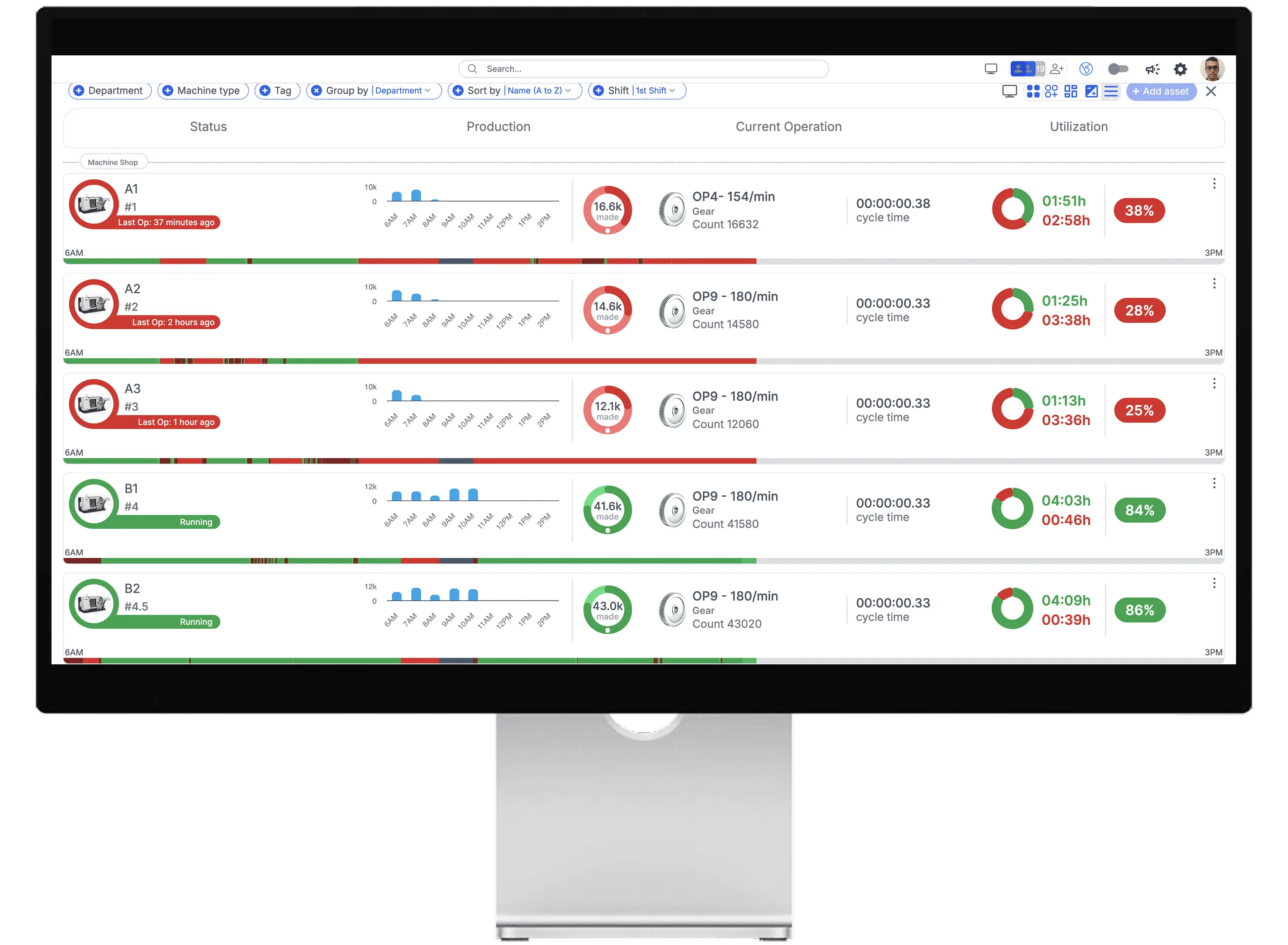

REAL-TIME PERFORMANCE & PRODUCTION TRACKING

See Every Second of Production. Hit Every Target.

Monitor OEE in real-time, spot bottlenecks the moment they occur, and track performance from individual machines to plant-wide operations.

- Live OEE monitoring and performance benchmarking across shifts

- Real-time production tracking

- Bottleneck identification and cycle time optimization

- Production variance alerts and target tracking

- Job progress visibility across all teams and production lines

DATA-DRIVEN DECISIONS

Reports That Actually Answer Your Questions

Stop digging through spreadsheets. Get reports customized to your shift schedules, operators, and departments. Track utilization, downtime patterns, and OEE metrics across across all machines.

- Daily, weekly, monthly, quarterly, and yearly reporting

- Custom shift-based performance analysis

- Operator and machine benchmarking

- Exportable data for stakeholder presentations

- Historical trend analysis

DOWNTIME INTELLIGENCE

Turn Downtime Into Insights

Unplanned stops don't have to stay a mystery. Automatically record every downtime event, identify root-causes, and spot trends over time. Know exactly when, where, and why issues occur.

- Automated downtime event recording

- Detailed root-cause analysis and categorization

- Trend identification for recurring problems

- Customizable alerts based on your specific time thresholds

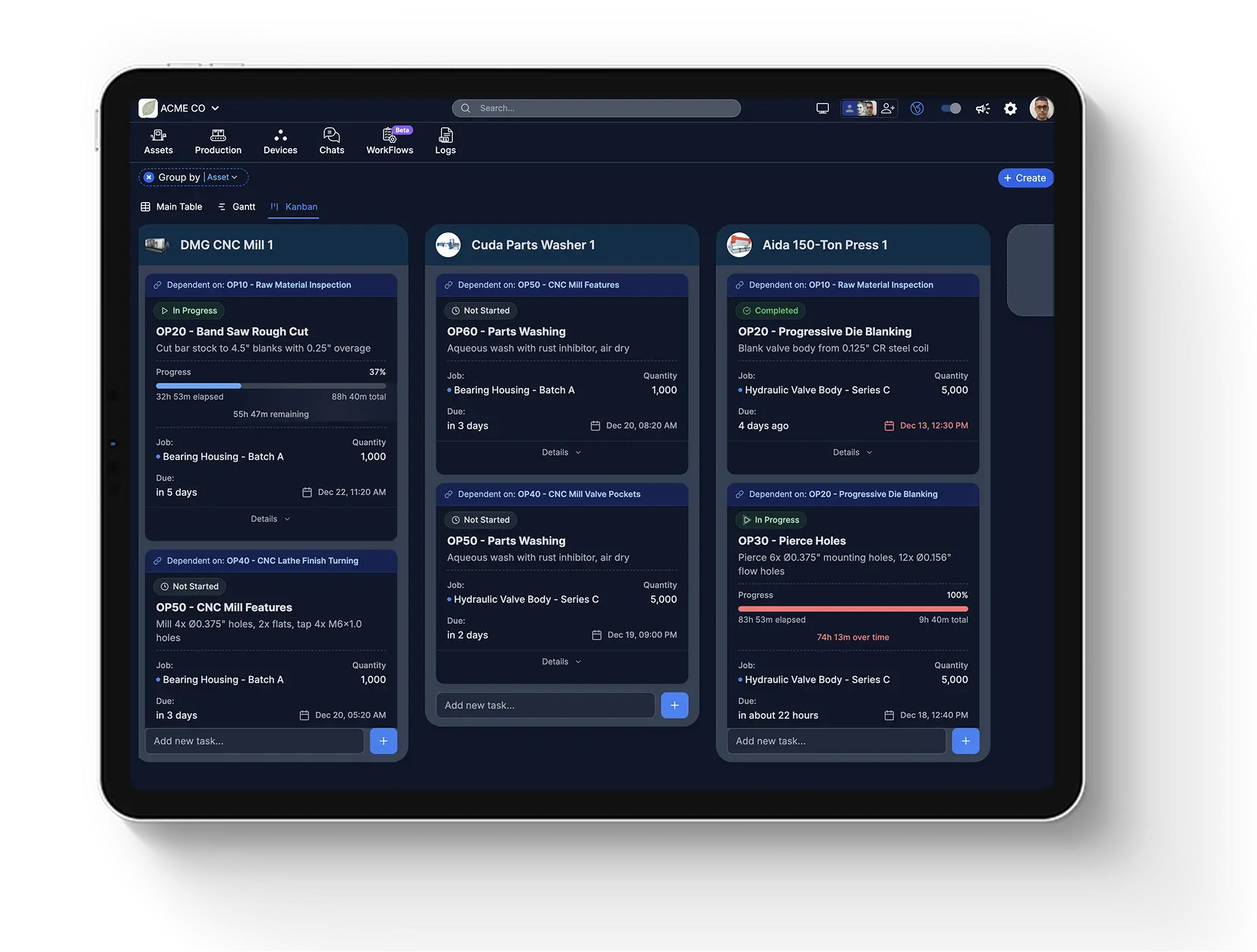

INTELLIGENT PRODUCTION PLANNING

Schedule Smarter. Execute Faster.

AI-powered scheduling that adapts to real-world conditions. Automatically prioritize jobs based on demand, monitor progress across all operations, and dynamically adjust when priorities shift.

- AI-driven job scheduling and auto-prioritization

- Demand-based production forecasting

- Live job status monitoring across all machines

- Dynamic schedule adaptation to changing priorities

- Drag-and-drop kanban interface for easy adjustments

SHOP FLOOR EMPOWERMENT

Tools Built For The People Who Build Your Products

Equip your operators with intuitive tools that make hitting production goals effortless. Real-time machine status, simplified downtime tracking, and instant collaboration and file sharing - all accessible from tablets, phones, or shop floor displays.

- Intuitive iPad and mobile interface for shop floor

- One-tap downtime classification and work order creation

- Real-time machine status visibility

- Instant alerts and notifications

- Seamless collaboration between operators and management

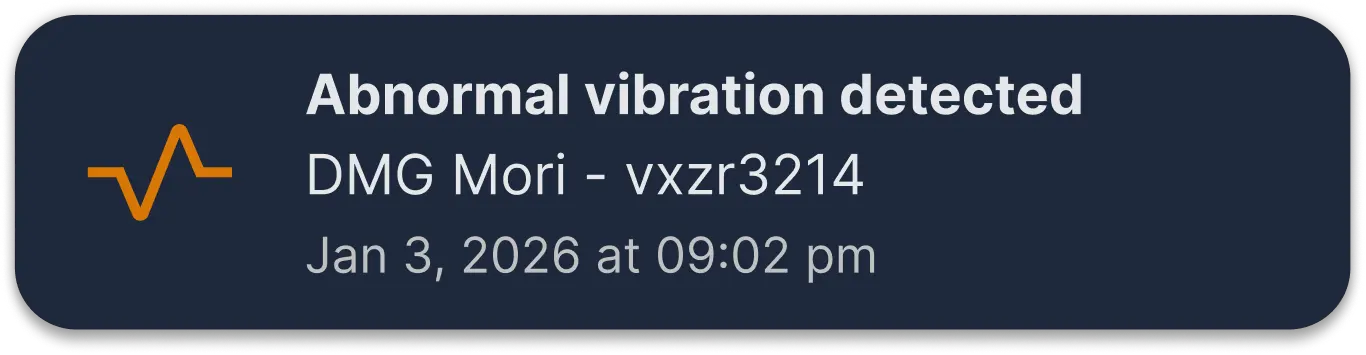

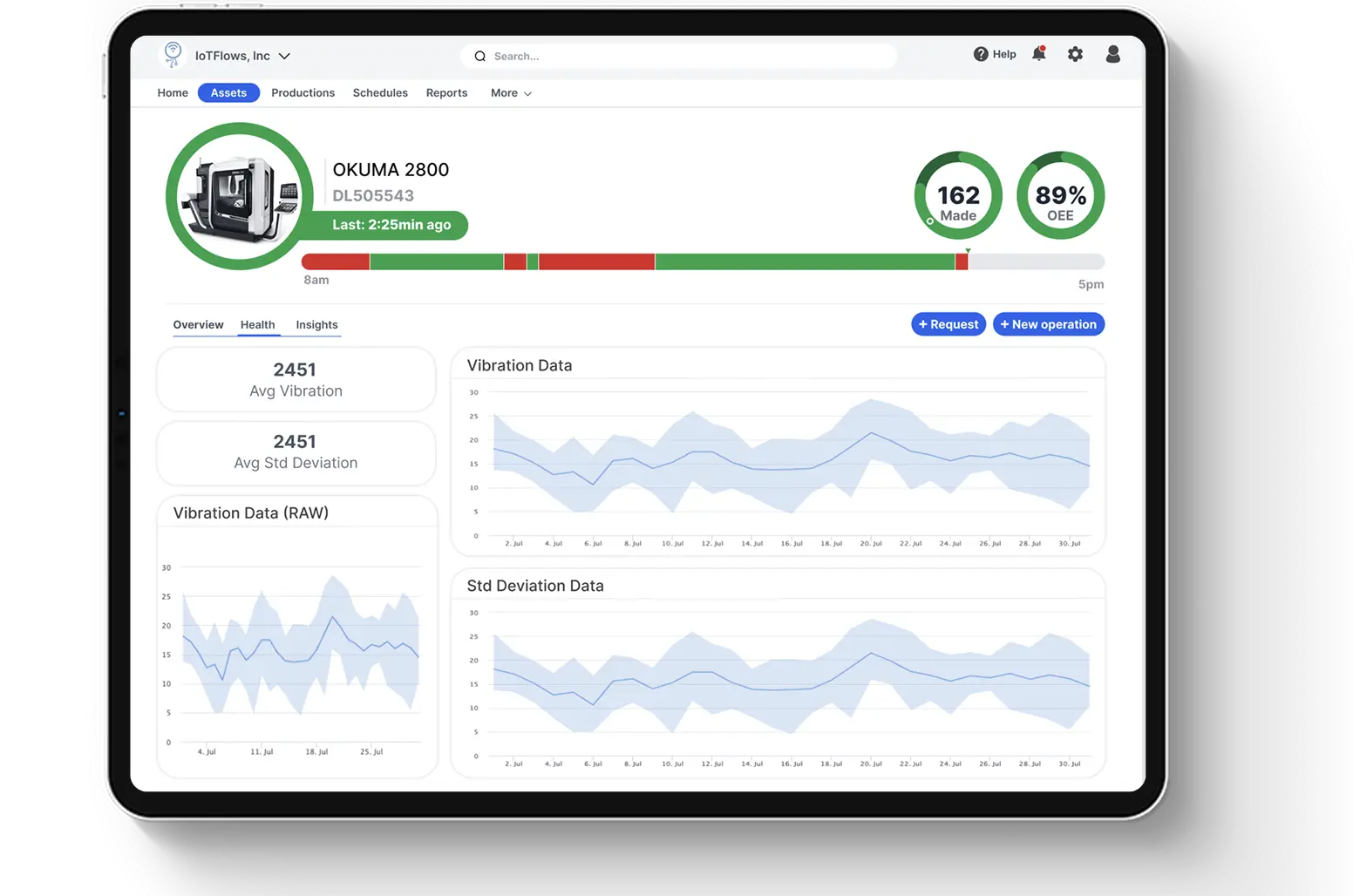

PREDICTIVE MAINTENANCE & MACHINE HEALTH

Prevent Equipment Failures Before They Cost You

Eliminate reactive maintenance. IoTFlows uses continuous vibration monitoring and AI-driven insights to predict equipment failures days or weeks in advance. Our analytics suite detects faults early and auto-generates work orders, enabling planned maintenance instead of emergency shutdowns - while optimizing machine performance to extend equipment life and maintain peak operating efficiency.

- Continuous vibration, acoustic, and temperature monitoring with wireless sensors

- Advanced health metrics: RMS, crest factor, kurtosis, peak velocity, FFT and spectral analysis

- AI-triggered maintenance tasks based on real-world machine conditions

- Bearing failure detection, misalignment alerts, and anomaly detection

- Reduce unplanned downtime by 30% or more

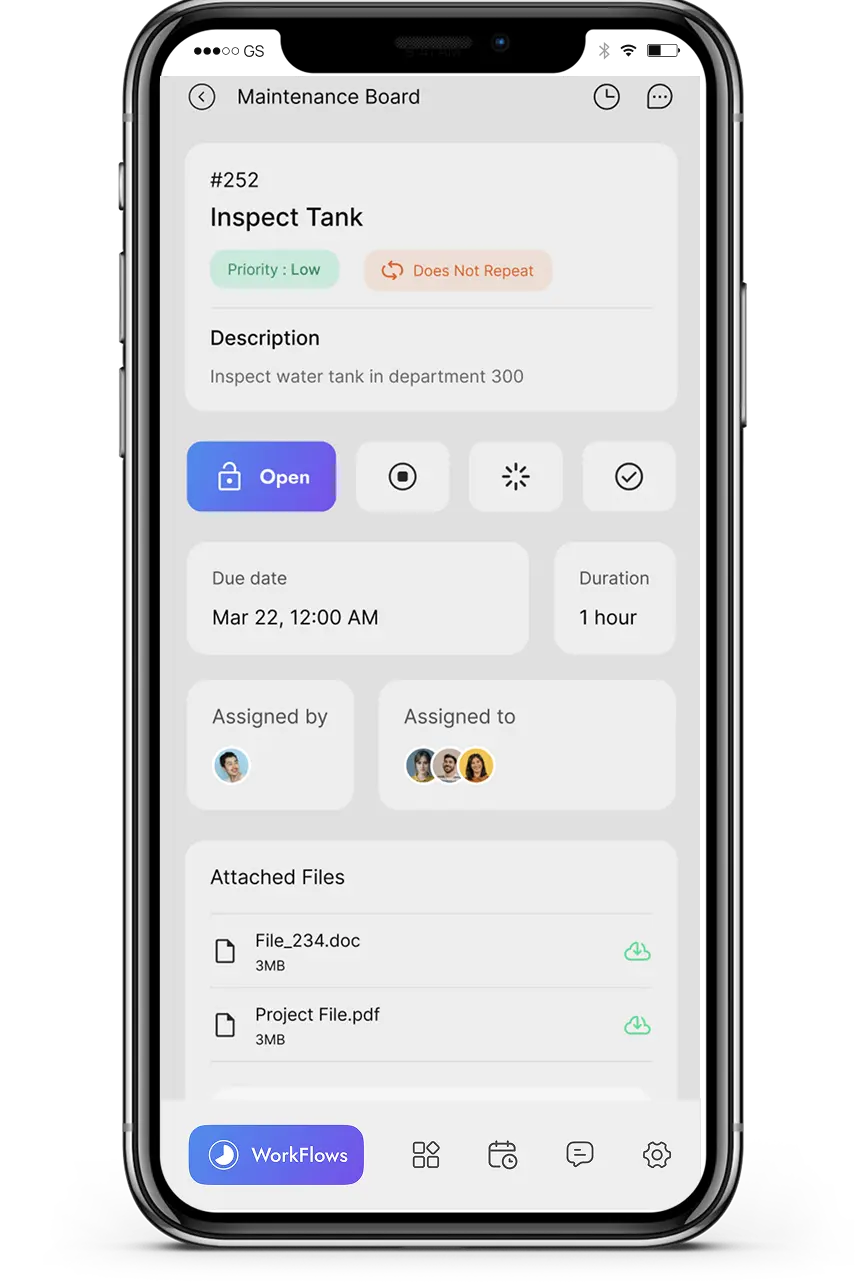

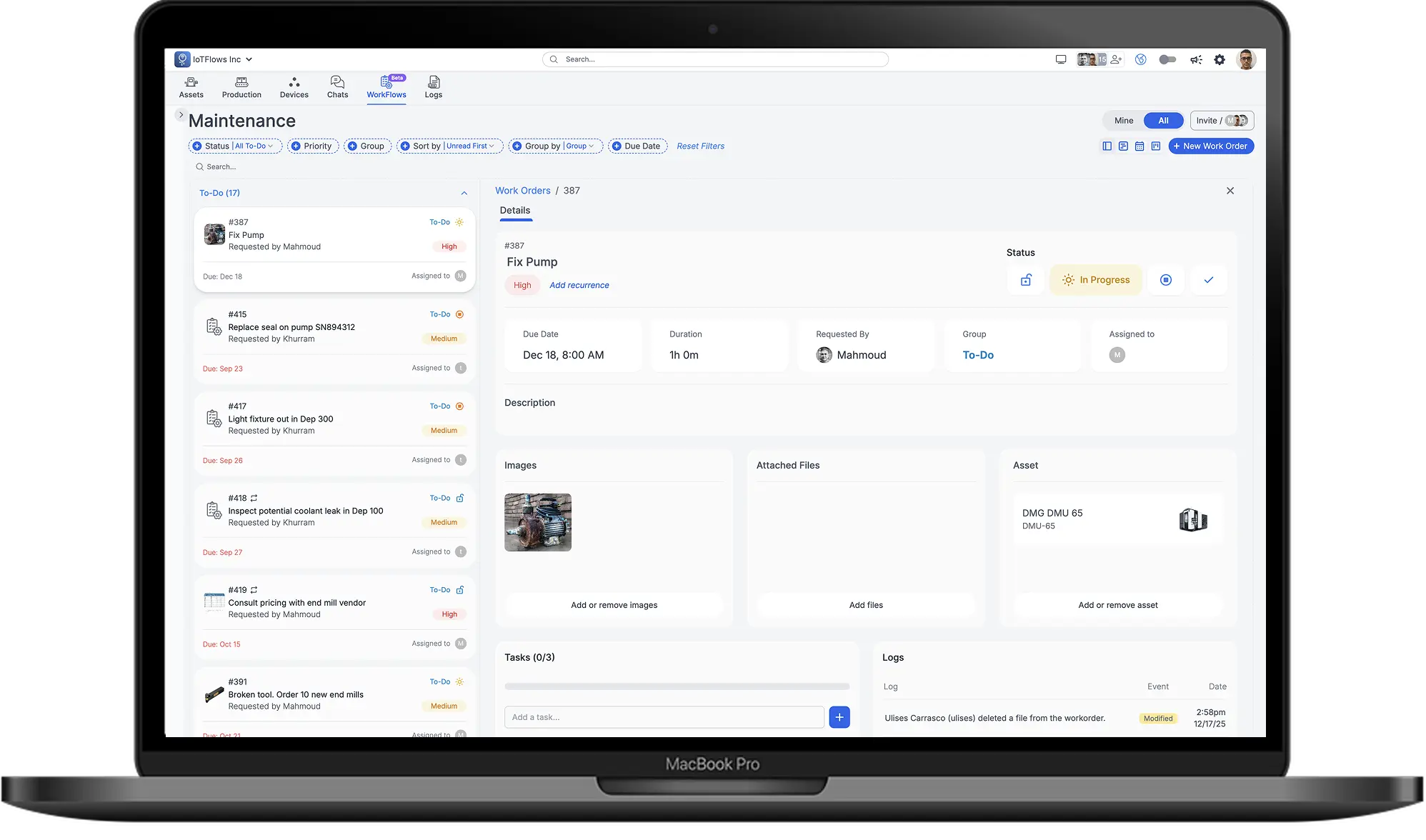

TEAM COLLABORATION & CONNECTED OPERATIONS

Align Teams. Respond Faster. Run Smarter.

Streamline communication and collaboration across your entire operation. IoTFlows empowers teams to submit maintenance requests, file issues, manage work orders, and share critical files - all from one unified platform. Track jobs in real-time, coordinate team assignments, and ensure everyone from operators to managers stays informed and aligned.

- Real-time mobile alerts and instant notifications

- Collaborative downtime classification and root-cause tracking

- Unified job progress visibility across all teams and shifts

- Work order integration and maintenance workflow automation

- Cross-functional communication from floor to executive level

ENTERPRISE INTEGRATION & DATA UNIFICATION

Break Down Data Silos. Automate Across Systems.

Stop manually bridging the gap between shop floor and top floor. IoTFlows unifies production data from across your facility—then seamlessly integrates with your ERP, and other business systems. Enable real-time visibility across departments, trigger automated workflows based on production events, and eliminate manual data entry. Your operations data becomes the single source of truth that drives smarter decisions and faster response times.

- Bi-directional ERP integration: SAP, Oracle, Epicor, and many more

- Seamless data sync capabilities eliminate manual entry and reduce errors

- Real-time production visibility for finance, operations, and management

- Event-driven automation: trigger workflows, notifications, and actions

- API-first architecture for custom integrations and advanced automation

Start Monitoring Your Machines Today

Join 100+ industrial customers who trust IoTFlows to optimize their operations.